Description

Note: This model only available in 460-480 volt single phase.

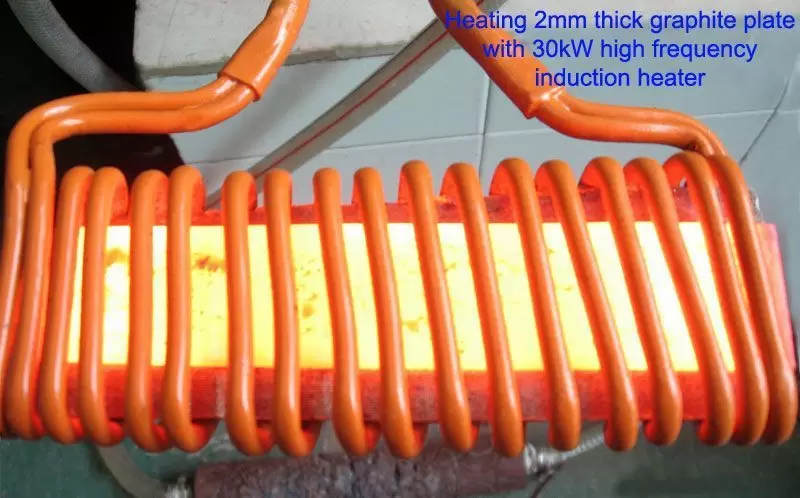

Across International IH series mid-frequency induction heaters are designed to operate between 30 and 80 kHz. Mid-frequency heaters are excellent for small parts heating, cutting, diamond tool brazing, soldering copper plumbing fittings, auto parts heat-treating, annealing of stainless steel containers and more.

Mid-frequency induction heaters are the simplest in terms of design and implementation. With their low cost of ownership and maintenance, they are the most popular and reliable machines. The 15kW models are especially popular for their large power capacity and small footprint at an affordable price. This makes them standard equipment for many factories, labs and workshops where 230V AC is available.

Main Features

- Dual-station with connection cables and hose let you separate the heater and controller up to seven feet, allow you to stay away from high temperature, dirty and corrosive environment and for a safer operation, or if you need to move the heater to your work pieces constantly during operation.

- Ease of use: just plug in the power and connect the water cooling system. Our simple instruction allows you to use the heater in 15 minutes.

- Light weight, portable (with built-in handle), instant heat and up to 90% energy savings.

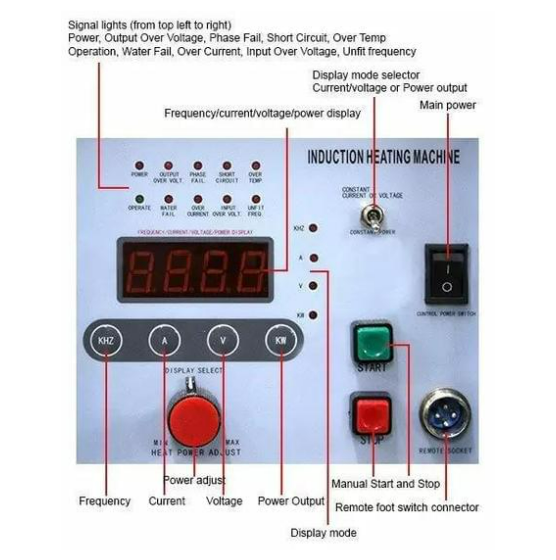

- Precise control with digital time and current displays.

- Remote foot switch for safer operation.

- Dual automatic and manual modes.

- Optional graphite and silica crucibles available. (melting material decides crucible type, weight and size of the material decide crucible size)

- Custom coil design (fixed coil or coil on a cable so it can be used by hand like a wand).

- ISO 9001:2008 registered manufacturer.

- We provide sample testing and custom made coils in our New Jersey facility.

Safety Features

- Overvoltage protection: machine shuts down when input voltage is over 495V. Overvoltage light will turn on and buzzer will sound continuously. Alarm and light shut off automatically when voltage goes below 495V.

- Overheat protection: if sensor detects heat radiatortemperature is over 55C, machine will shut down, overheat light will turn on and buzzer will sound continuously. Increase water pressure or lower water temperature until alarm goes off itself.

- Overcurrent/malfunction protections: machine will shut down, indicator light turned on and buzzer sounds continuously if one of these situations occurs:

- One of the machine parts becomes overheated

Interfering signal detected - Short circuit between work pieces and induction coils

- Machine malfunctions

- Induction coils touching each other

- Input voltage is too low

- Low water pressure protection: if water pressure goes below 29 PSI, machine will shut down, water protection light will turn on and buzzer will sound continuously.

CAUTION

- Always wear protective gear and goggles when operating the machine. Crucibles must be covered all the time during operation. Across

- International is not responsible for any injury or damage caused by misuse.

- Do not run no-load operation for a long period of time, it might cause damage to the machine.Circulating water must be pure, clean and below 45C.

- Machine must be grounded properly all the time during operation.

- Do NOT use single-turn coil if coil diameter is smaller than 4 inches, it will cause high frequency damage to the machine.

- Thread tape (or related material) is absolutely prohibited during installation of induction coils.

Specifications

| Max. input current | 19 A (25A 3-phase circuit breaker required) |

| Power | 460 VAC, 50/60Hz, three phase |

| Power distribution cord | 10-gauge 4-conductor Max 25A (10/4 SOOW for 3 PH system) |

| Output frequency | 30-80 KHz |

| Heating/retaining current | 200-1000 A (displayed on control panel) |

| Max. oscillating power | 25 KW |

| Max Input power | 15 KW |

| Duty cycle | 80% |

| Heating/dwelling/cooling timers | 1-99 seconds |

| Water pressure | ≥ 29 PSI (0.2 Mpa) you may use tap water and water pump (>1/4HP & >240 Gph) |

| Water temperature | 25-30°C |

| Water flow | 0.5-1.3 gallons (2-5 liters) per minute |

| Induction coil | See detail specs below, we will make coils according to your requirements |

| Unit Weight | Power supply: 55 Lb, capacitor: 35 Lb |

| Shipping weight | 115 Lb |

| Size | 22x22x23″ |

| Remote foot switch | 7 feet |

| Max. melting capacity | 7 Lb (gold, silver, copper), 2 Lb (steel, aluminum) |

Standard package

| Part description | Quantity | Part image |

| IH25AB power supply | 1 pc |  |

| IH25AB capacitor | 1 pc | |

| Connection cable | 1 set |  |

| Foot switch (7 ft) | 1 pc | |

| Induction coil | 2 pcs |  |

| Hose Clamps | 8 pcs |  |

| 0-5 V Cable | 1 pc | |

| Fuse | 5 pcs |  |

| Induction coil adapter (to protect the coil connectors on the machine, good for users who change coils frequently) | 2 pcs | |

| Brass Accessories and fittings | 4 pcs |  |

| User’s manual | 1 pc |

Reviews

There are no reviews yet.