Description

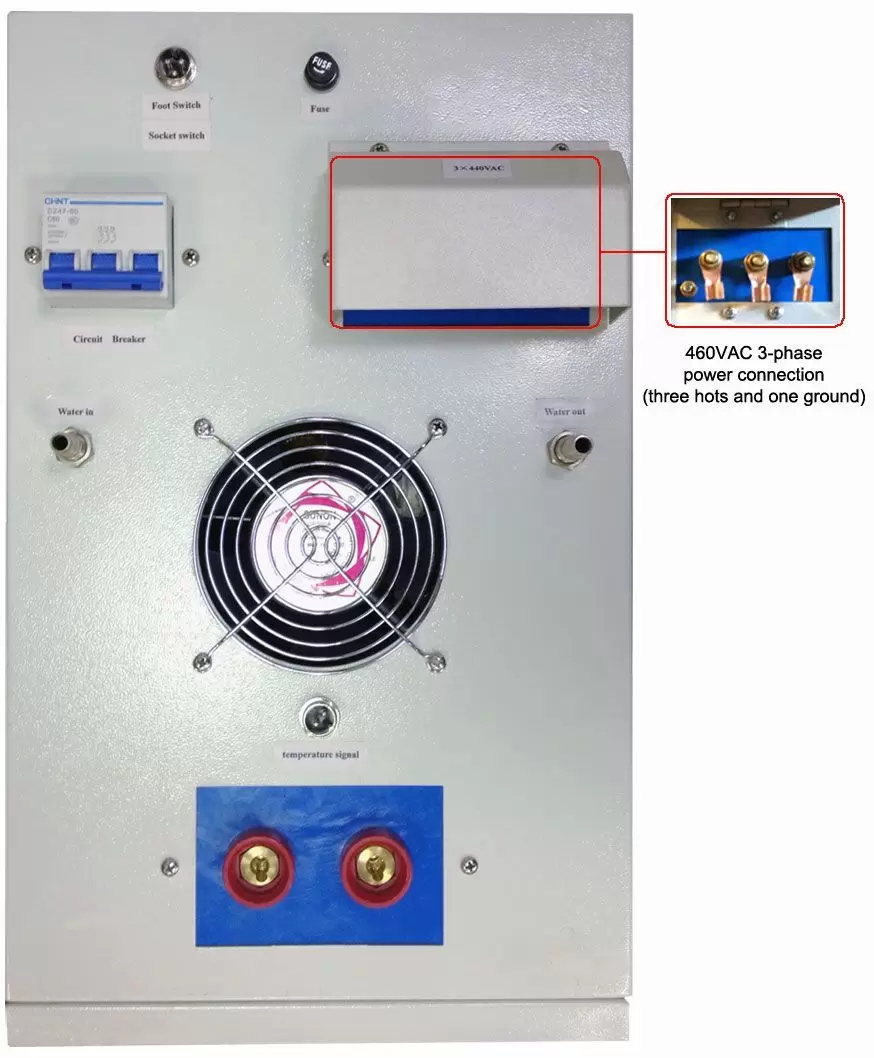

Note: This model only available in 460-480 volt three-phase.

Across International’s IHL series 1 kHz to 20 kHz low frequency induction heaters are good for a wide range of applications including deep heat penetration for full hardening processes, steel rod forging, tempering of pressing dies, pre-heating for welding, and melting of metal batches over 4 lbs. They are not limited to ferromagnetic materials, so nonferrous metals can also be used effectively.

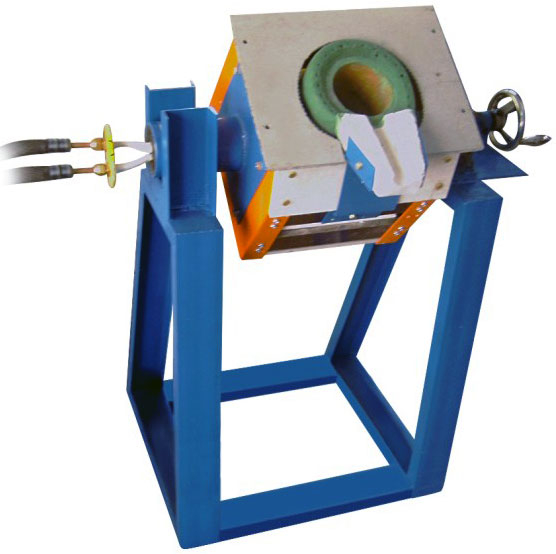

There are three major components to the system: the power supply, the compensating capacitor/transformer and the induction coil/smelting crucible. Our heaters automatically adjust to the best resonant frequency in order to achieve the most efficient overall heating results based on our customer’s requirements which include heat penetration, heating efficiency, operating noise and electromagnetic homogeneity. Two of our most popular low frequency machines are the Melting Furnaces with Tilt-Pour Melter and Auto-feeding Rod Heating Furnaces for Forging.

Safety Features

- Overvoltage protection: machine shuts down when input voltage is over 495V. Overvoltage light will turn on and buzzer will sound continuously. Alarm and light shut off automatically when voltage goes below 495V.

- Overheat protection: if sensor detects heat radiatortemperature is over 55C, machine will shut down, overheat light will turn on and buzzer will sound continuously. Increase water pressure or lower water temperature until alarm goes off itself.

- Overcurrent/malfunction protections: machine will shut down, indicator light turned on and buzzer sounds continuously if one of these situations occurs:

- One of the machine parts becomes overheated

Interfering signal detected - Short circuit between work pieces and induction coils

- Machine malfunctions

- Induction coils touching each other

- Input voltage is too low

- Low water pressure protection: if water pressure goes below 29 PSI, machine will shut down, water protection light will turn on and buzzer will sound continuously.

Other Features

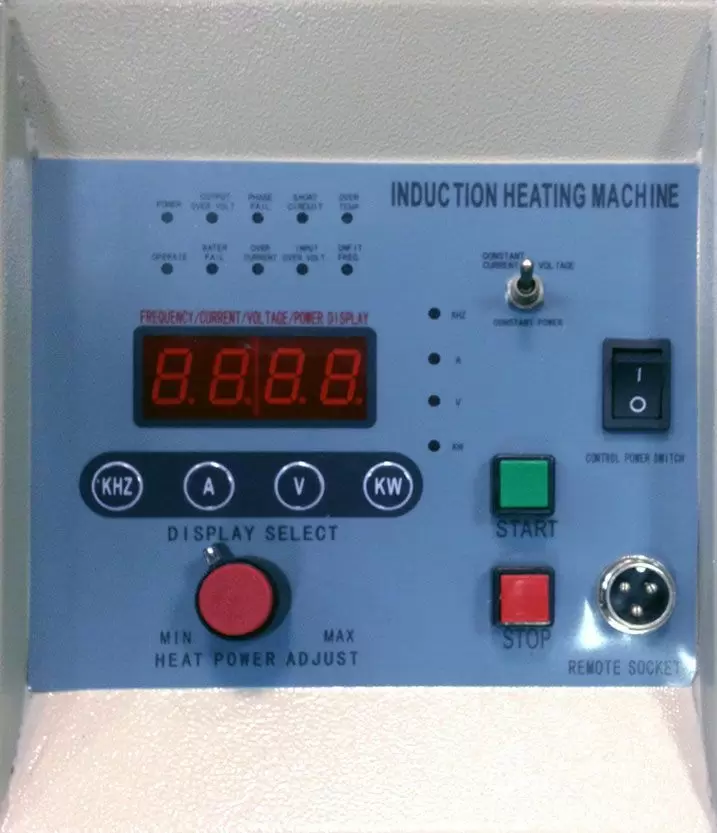

- Digital output, frequency and current displays

- Automatic and manual modes

- Comes with one graphite crucible. Additional crucibles available at extra cost

- ISO 9001:2008 registered manufacturer

CAUTION

- Always wear protective gear and goggles when operating the machine. Crucibles must be covered all the time during operation. Across

- International is not responsible for any injury or damage caused by misuse.

- Do not run no-load operation for a long period of time, it might cause damage to the machine.Circulating water must be pure, clean and below 45C.

- Machine must be grounded properly all the time during operation.

- Do NOT use single-turn coil if coil diameter is smaller than 4 inches, it will cause high frequency damage to the machine.

- Thread tape (or related material) is absolutely prohibited during installation of induction coils.

Specifications

| Max. input current | 31 A (min. 40A 3-phase circuit breaker required) |

| Power | 460 VAC 50/60Hz three phase (380V available upon request) |

| Power cord | 6-gauge 4-conductor Max 45A (6/4 SOOW for 3 PH system) |

| Output frequency | 1-20 KHz (actual frequency depends on type, size of work pieces and heating requirements) |

| Input power | 25 KW |

| Output current | 5-45 A |

| Output voltage | 70-550 V |

| Duty cycle | 100% (24 hours continuous use) |

| Water pressure | ≥ 0.2 Mpa (29 PSI) you may use tap water and water pump (>1/4HP & >240 Gph) |

| Water flow | > 1.6 gallons (6 liters) per minute |

| Unit dimensions (DxWxH) | Power supply: 55 Lb, 18 x 10 x 18″ Transformer: 18 x 10 x 17″ (or 19 x 16 x 17″, depends on requirements) Tilt-pour: 26 x 22 x 27″ (or 26 x 24 x 37″, upon request) Graphite crucible: 6.7″ OD, 7.9″ height Optional 4P chiller: 37 x 22 x 54″ |

| Shipping dimensions (DxWxH) | 30 x 26 x 26″ (induction heaters) 43 x 27 x 35″ (tilt-pour) |

| Shipping weight | 180 Lb (induction heaters) 220 Lb (tilt-pour) |

| Max. melting capacity | 22-44 Lb (copper, silver, gold), 17 Lb (steel), 8 Lb (aluminum) See melting point of various metals and alloys |

Standard package

| Part description | Quantity | Part image |

| IHL25K power supply and capacitor | 1 set |  |

| Tilt-pour melter with one graphite crucible | 1 set |  |

| Power cable btw power supply & capacitor x 1 Temp cable btw power supply & capacitor x 1 Water cooled cable btw capacitor & melter x 2 | 4 pcs |  |

| Remote on/off switch | 1 pc | |

| Water cooling fitting | 1 set | |

| Stainless steel hose clamp | 1 set | |

| Fuse | 1 set |  |

| Operation manual | 1 pc |  |

Reviews

There are no reviews yet.